Floor Trusses

Floor trusses are the solution to many floor framing problems. Architects, engineers and contractors are using floor trusses to create high quality, squeak-free construction with the added benefits of reduced framing time, waste, and callbacks. Design versatility and the open space provided between the chords and webs of floor trusses for mechanical and plumbing runs offer tremendous advantages for today’s complex and sophisticated building designs.

Benefits of a Floor Truss

- Floor trusses are built with 2x4s or 2x3s with a wide, stable bearing surface that is easier to work on and around.

- The wide nailing surface provides for easy gluing and quick, accurate attachment of sheathing, reducing squeaks and improving floor performance for the life of the structure.

- The spacing of floor trusses allows for maximum structural efficiency and speed of installation.

- Stiffness and strength can be designed into the floor truss, creating a more solid floor.

- Special bearing, cantilever and balcony details are easily built in.

- Shrinkage, warping or twisting are minimized.

- Long spans and girder truss options reduce the need for intermediate bearing walls, beams, columns and footings – saving time and construction costs.

- The open web configuration leaves plenty of room for plumbing, electrical and mechanical runs.

- Floor trusses provide opportunity for shallower or deeper depths.

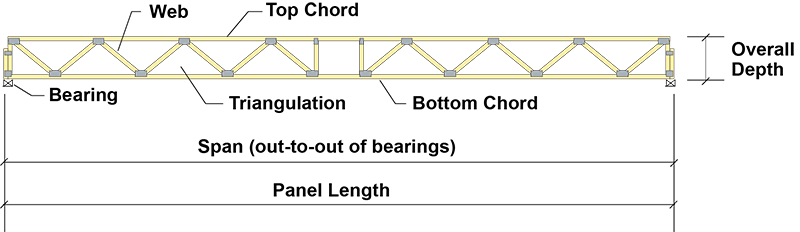

Elements that Make a Floor Truss

Structural support, usually a beam, wall, or post that is designed by the building designer to carry the truss reaction loads to the foundation.

Every truss requires at least two bearings, or points, to transfer its loads to. Typically, it is a 2x4 or 2x6 wood frame wall or panel in residential construction but can also be a light gauge steel wall or block wall in commercial or industrial applications. Likewise, bearings can be beams, ledgers, headers, or posts made from any of the above-mentioned materials. Regardless, the bearing must be strong enough to support the loads transferred from the trusses above. If the bearing material is not strong enough, crushing can occur when the truss is under designed loads. This results in serviceability issues like cracked sheetrock and dips in ceilings above and floors below. In extreme cases failure can occur, albeit rare.

Other trusses can also be used to support adjacent trusses connected at some type of angle, usually 90 degrees with a metal connector joist or truss hanger. In some instances with very light loads, trusses can be nailed together to act as a bearing condition. The carrying truss that supports other trusses is known as a girder truss. The bearing supporting the girder truss is most likely to suffer from the crushing effects mentioned above. Enhancements can be made to the side of the truss where it connects to the wall known as bearing enhancers or squash blocks to better transfer the loads of the girder over a greater surface area of the bearing.

Additional bearings can be designed to the interior area to help support the truss mid span, lessening the load reactions at the outer bearing and potentially reducing the amount of lumber and the size of the metal connector plates required to build the truss. These bearings need to be supported by an adequate support structure downward though the wall to any floor systems below and into the foundation system of the structure.

Bearing width knowledge is critical to truss design to ensure the truss meets expectations in the construction process. An example of this is the seat cut of a scissors truss. If the bearing size varies from the truss design, the ceiling area can be impacted where it meets the wall and modifications will be necessary when installing drywall or other finish products.

Typically, trusses are connected to the bearing temporarily with nails and permanently with a metal connector designed for uplift and lateral load considerations.

Inclined, or horizontal member that establishes the bottom of a truss, usually carrying combined tension and bending stresses.

The bottom chord is one of three key components to any truss. In addition to the top chord and webs, the bottom chord is used to transfer forces to the truss bearings. The bottom chord typically carries combined tension and bending stresses. For traditionally spaced trusses, the bottom chord is cut out of 2x4 or 2x6 dimension lumber but can also be cut out of 2x8, 2x10, 2x12, and even LVL material for roof trusses. Factors that determine the size of the bottom chord include on-center spacing, dead loads applied to the truss, span, and if there is any pitch applied to the bottom chord. An example of this is a vaulted ceiling application framed by scissors trusses. In some cases a live load can be applied to a bottom chord, either for storage purposes or if there will be movement within the truss, such is the case in an attic truss.

In floor truss applications, 2x4 or 2x3 material is typically used with the wider portion of the board resting on the bearing or what is known as a 4x2 configuration. Orienting the chord material in a 4x2 manner creates a very stable truss that allows installers the ability to walk easily across members without tipping the truss while installing additional members or floor deck sheathing.

In standard heel applications of roof trusses, the bottom chord is cut on each end at an angle consistent with the roof pitch of the truss. This creates additional surface area for the two members to transfer forces and allows for them to be plated together, creating a strong, resilient joint. On the outermost part of a bottom chord a small vertical cut, known as a butt cut, is created to give the truss a starting and ending point that can be aligned with the bearings below. The butt cut is typically ¼” on standard heel trusses but can be increased for a taller heel. When combined with a slider or stacked chord, a raised heel, sometimes known as an energy heel, can be created to raise the profile of the roof and increase the amount of insulation and ventilation over the bearing of the structure.

The bottom chord is intersected by the top chord and web members at various points throughout the truss, creating a joint secured by metal connector plates. A bottom chord can be multiple pieces of lumber secured by a metal plate known as a splice, either at a joint or mid panel. While a vast majority of trusses will have bottom chords of the same species and grade, changes in both lumber species and grade are possible at splice points. This is most often seen in attic trusses where the bottom chord is increased in the living space and additional loads are applied and then reduced near the bearings to reduce expense.

A preassembled unit of floor joists, subflooring, finished flooring, and sometimes ceiling below supported by walls, columns, or beams.

Floor panels, also known as floor decks, are a factory-built portion of a floor system with joists that are glued and fastened with sub floor sheathing at specified on-center spacing for the particular joist depth, material, and sheathing. Common joist materials include floor trusses, I-joists, and dimensional lumber such as 2x10 and 2x12. Floor panels offer a very quick method for setting a floor system in the field, typically using a crane. Occasionally floor panels will have a ceiling material applied to the underside of the panel in the factory, further speeding up the construction process in the field. Typical constructions principles still apply, floor trusses are required to be supported by and fastened to structural supports such as walls, columns, or beams.

Vertical distance between bearing and the uppermost point of the peak.

Floor truss depth is measured from the bottom chord to the top chord and typically maintains that height throughout the span of the truss. Most floor trusses range from 16” to 24” in depth. The overall depth of a floor truss is typically determined by a building designer depending on the mechanical purposes of the floor truss. Floor trusses are a great way to conceal mechanical, electrical, and plumbing systems as their open web design creates a naturally accessible space for various trades to ”hide” their work. Floor trusses can also be designed with a chase for air ducts to run perpendicular to the truss layout. Overall depth is a critical factor in determining which air handling systems can be designed for use in a given space.

Manufacturing capabilities for individual component facilities dictate the maximum overall depth that can be manufactured at that location. Most floor truss manufacturing machines are capable of producing floor trusses up to 24”, but that doesn’t mean a taller floor truss couldn’t be built if the manufacturing equipment was capable.

Panel Length: Horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord.

Panel Point: Location on a truss where the web members and top or bottom chords intersect and are connected by metal connector plates.

Trusses are made up of a series of panels, or the horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord. Panels are imperative to the triangulation of the truss that allows the transfer of forces through the truss members and ultimately to the bearings.

Panel length is determined by the truss technician and typically determines what size material is used for the top or bottom chord. The greater the panel length, the more likely the truss technician is to use wider width material. The truss technician’s primary task is to design the most efficient truss while meeting loading and design conditions as well as adhering to a variety of code, safety, and standards requirements.

Panel points are located where web members intersect with top or bottom chords, which are connected by metal connector plates. Panel points determine the length of the panel and webbing formation of the truss. Shifting panel points even small distances can impact the efficiency of the truss and transform a truss that doesn’t pass design requirements to a truss that does. This is particularly evident when point loads are applied to a truss.

Horizontal distance between outside edges of exterior bearings.

Span is a necessary component of any truss. It is the horizontal distance between two exterior bearings and is typically the width of the structure. Special attention should be taken not to confuse any cantilever portion of the truss with its span. For example, if the walls of the structure are spaced 24’ apart and the truss has a 4’ cantilever on one side, the overall truss length would be 28’ with a span of 24’ and a 4’ cantilever. Truss span can vary widely from as small as 1’ (or smaller if necessary) to over 100’ in length. Truss length is typically limited by manufacturing and transportation capacities for a specific manufacturer. Trusses over 60’ in length are considered ”long span trusses” and require special installation and bracing considerations. Visit SBCA’s website(link is external) for more information on long span truss installation.

Anyone wishing to order or request a quote for trusses will need to know the span. In simple structures it will typically be the width of the building. In more complicated buildings, it will be taken off the construction documents and likely determined by a truss design and/or layout software specific to the component manufacturing industry.

Inclined or horizontal member that establishes the top member of a truss.

The top chord is one of the three key components to any truss. In addition to the bottom chord and webs, the top chord is used to create the upper perimeter of the structure, or the roof. The top chord is configured to resist live loads such as those applied during construction, as well as wind loads, snow loads and others. It also resists more permanent dead loads like sheathing and roofing materials. For traditionally spaced trusses, the top chord is cut out of 2x4 or 2x6 dimensional lumber but can also be cut out of 2x8, 2x10, or 2x12 material for roof trusses. Factors that determine the size of the top chord include on-center spacing, dead and live loads applied to the truss, span, and pitch applied to the top chord.

The top chord is intersected by the bottom chord and web members at various points through the truss creating a joint that is secured by metal connector plates. A top chord can be multiple pieces of lumber secured by a metal plate known as a splice, either at a joint or mid panel. While a vast majority of trusses will have top chords of the same species and grade, changes in both lumber species and grade are possible at splice points.

In typical trusses with an overhang, the top chord is extended past the bearing over the bottom chord to create an eave condition for the structure. Most top chords are cut with a plumb cut at the peak and overhang and a square cut at splices.

For floor trusses, the top chord material is usually cut from 2x3 or 2x4 material, but instances utilizing 2x6 top chord material for floor trusses can also be found. Typically in floor trusses, the material is oriented in a flat or 4x2 position. Orienting the chord material in a 4x2 manner creates a very stable truss that allows installers the ability to easily walk across members without tipping the truss during installation of additional members or floor deck sheathing.

The act of forming rigid triangles with objects adequately fastened together.

Triangulation is the engineering practice of forming rigid triangles together with adequate fasteners at the joints. It typically involves the use of triangular shapes to give stability to structures. In roof and floor trusses, wooden triangles are used to pass compression and tension forces throughout the structure to its bearings. Triangles are the simplest geometric figure that will not change shape when the lengths of the sides are fixed and offer significant structural stability in design.

Members that join the top and bottom chords to form the triangular patterns typical of trusses. These members typically carry axial forces.

The web member is one of three key components to any truss. In additional to the top and bottom chords, webs typically carry axial forces to the chords that eventually pass to the truss bearings. The vast majority of trusses utilize 2x4 dimensional lumber but webs can vary from 2x3 up to 2x12 lumber depending on the design. The grade and species of lumber used for webs is typically different from the chords of the truss to drive economic efficiency. Factors that impact the size of web members include on-center spacing, dead and live loads applied to the truss, span, and pitch, among others.

In floor truss applications, 2x3 or 2x4 material is used to cut webs. When oriented on the flat face of the board, webs will be cut with bevels on each end to create more surface area at the joint for a better fit. In some instances, square cut floor webs can be used but result in larger plates at the joint. Floor trusses oriented in a 4x2 or 3x2 manner are much more stable than floor trusses oriented on edge, allowing installers the ability to easily walk across members without tipping or rolling the trusses during installation while floor decking and bracing is applied.

Webs are typically cut with many angles on each end to allow for a tight fit at the joint. Sophisticated automated computer-driven saws are used to cut webs and other truss parts with very specific angles and lengths that allow for intricate joints and increased surface areas to aid in the transfer of forces. Linear saws are able to quickly cut differing webs out of one piece of lumber thereby minimizing waste. Component saws are utilized to cut high volumes of webs of the same configuration out of a fixed length board using 5 or 6 saw heads. Pull saws, either manual or semi-automated, are used to cut a variety of parts including webs in low quantities. Common trusses are typically designed with symmetrical webs to reduce the number of saw setups and make the overall truss fabrication process less complicated.

Often web members in compression require continuous lateral restraints (CLR) to prevent buckling under the applied design loads. Webs requiring CLRs will be denoted on the Truss Design Drawing with a rectangle with an “X” through it or a rectangle fully blackened on the web. CLRs attached to similar adjacent trusses are required to have a diagonal brace to transfer the forces from the CLR into a lateral force resisting system such as the roof or ceiling sheathing. Alternatively to CLRs, individual web restraints such as scab, “T,” or “L” reinforcements can be installed in the field on the truss in instances where a CLR is not possible due to differences in web patterns of adjacent trusses. Another alternative to field applied restraints are factory installed stacked webs and proprietary metal reinforcements that have been specially designed for this purpose.

For more information on web member restraints and temporary and permanent truss bracing in general, refer to BCSI.