How Do Component Manufacturers Take Their Products to Market?

The following content is part of SBCA’s Construction Industry Workflow Initiative, which is exploring how the construction industry currently functions and the role component manufacturers play within that structure. Your feedback is encouraged to help us complete this project, email info@sbcacomponents.com to provide your input.

This article is a general approach to defining the variety of methods in how CMs sell and distribute their products to market and isn’t meant to encompass all methods.

In this article the term “Builder” is intended to be interchangeable with the term “General Contractor”, each of which hold the ultimate responsibility for constructing a structure.

Component manufacturers (CMs) bring their products to market in a variety of ways, typically driven by historical tendencies in individual, local markets. While there is no right or wrong way to sell engineered framing components, it’s valuable to understand the variety of methods and what may or may not work in your market. The methods are largely dependent on installation labor relationships in the market and builders’ relationships with their primary building material suppliers. Methods can even vary by individual product lines. In other words roof trusses can be sold in a different manner from wall panels, floor trusses or other engineered wood products. Below is one set of flow charts with descriptions of the variety of ways CMs sell their products.

1. CM Sells Components Direct to Builder

The most direct distribution approach for CMs is to sell their products directly to the builder. This is typical of smaller builders/general contractors who perform much of the labor themselves as opposed to subcontracting it to more specialized installation trades. Larger builders may or may not have an internal installation/framing crew to install components or might not inform the CM of how the components will be installed for a particular project. Regardless who performs the installation, the CM interacts directly with the builder with respect to the construction documents, all plan and spec submittals required, receipt of appropriate approvals, any RFIs and ultimately the delivery of products and design and engineering services.

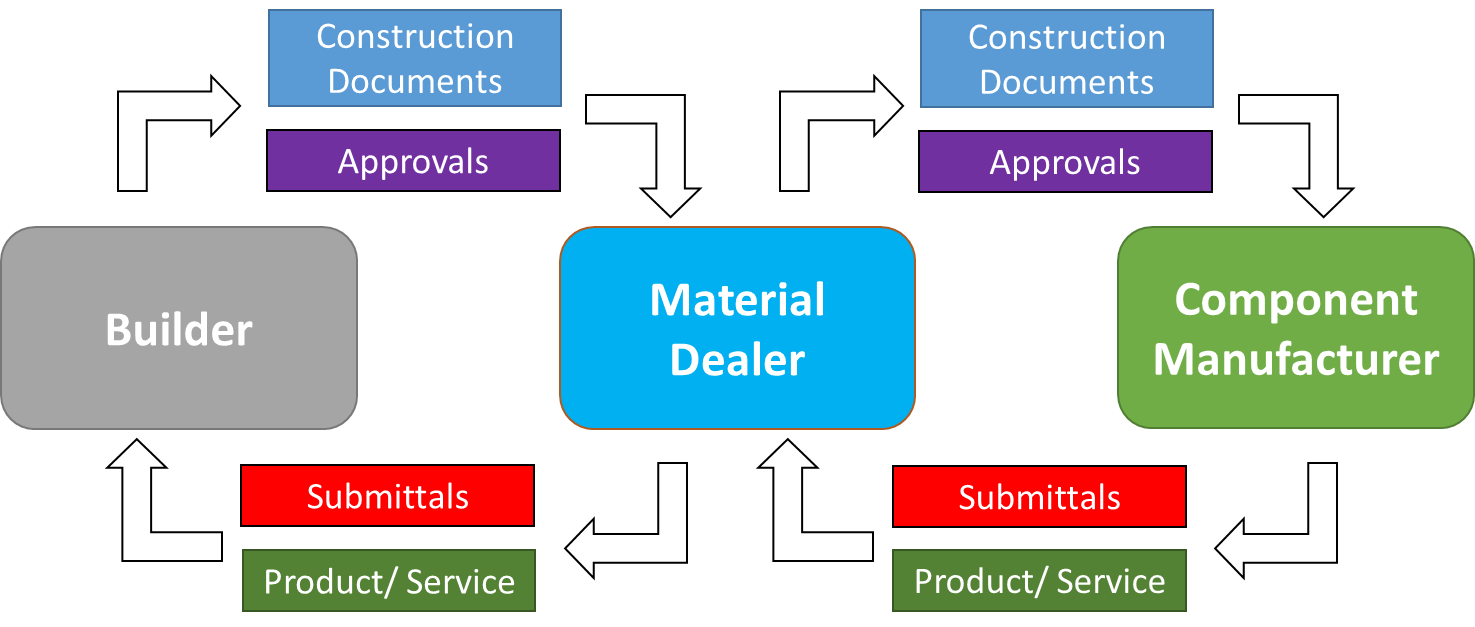

2. CM ‘Two Steps’ Components through a Material Dealer

Another popular method for distributing components, without CM knowledge or involvement with the builder or installation labor is through a building material dealer, distributor, lumberyard or other type of reseller. The CM will receive the construction documents and initial project lead from the material dealer and will typically route submittals through the material dealer ultimately to the builder for approval who will then return the approvals back through the material dealer to the CM.

Occasionally the material dealer will remove themselves from the submittal/approval process in order to streamline communications but will certainly participate in the invoicing process in order to protect their financial interest in the project. Delivery of components in this model will typically be to the jobsite, but can be delivered directly to the material dealer for subsequent delivery to the jobsite or held for pickup by the builder/end user if the geometry of the component package allows for easy transport. This “two step” distribution method is popular amongst material dealers who desire to offer a complete framing solution that includes components to their customers.

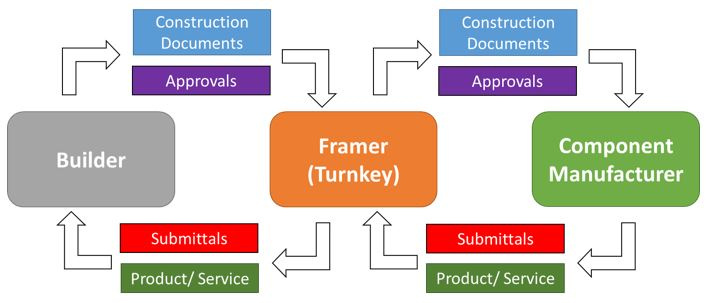

3. CM Contracts with a Turnkey Framer

Turnkey framers earn their name as they provide a “turnkey” solution to builders, which includes structural framing components installed by one provider under a single contract. Turnkey framers, in turn, source component solutions directly from CMs. This solution puts the installation labor and CM on the same side of the value proposition equation and allows the framer to distribute construction documents, review submittals, send approvals and receive the product directly. Turnkey framers are more likely to communicate specific preferences and develop trust with a CM in this distribution model. CMs are in a better position to understand installation concerns and can communicate potential efficiencies in design and installation to impact the framer’s overall performance and drive down installation time and costs.

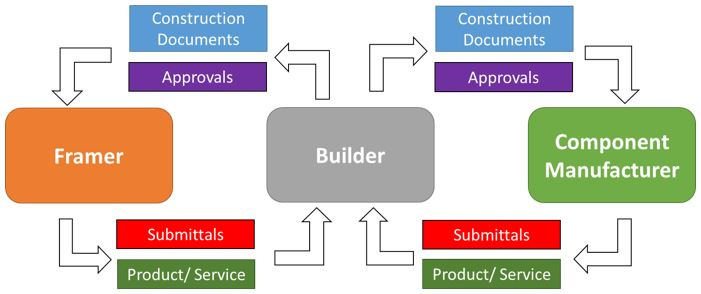

4. Builder Contracts Components and Framing Labor Separately

Builders often choose to source components and installation/framing labor separately. In this distribution model, builders will separately circulate construction documents and process submittals from framers and CMs separately while also separating the actual installation from the supply of components. The majority of communication between the CM and framer is channeled through the builder. This model can work favorably for the builder, often soliciting the lowest price for goods and services but can also pit the installer against the supplier in what is often viewed as a zero-sum proposition where one service provider or supplier’s gain comes at another’s loss through the use of “back charges” or further charges for installation services or RFIs that lead to additional products being needed to complete the project.

5. Integrated CM/Framer

Similar to a Turnkey Framer, another approach to component distribution is an integrated CM who employs framing labor to provide builders a single solution, powered by the CM. This method places the installation labor and CM on the same side of the equation where both benefit from a singular success. Communication regarding components and installation methods are internal to integrated CM providers which focuses attention on the best, most efficient installed solution opposed to tactics and solutions that focus on lowest bid cost to get the job, versus the best installation approach to make the install process easier.

Varying approaches to component distribution exist throughout the country and vary by market with many CMs interfacing with two or more of these distribution models. This list is not meant to be exhaustive but represents the most common distribution models today. To add to this list or point out areas where improvements can be made contact info@sbcacomponents.com.