Adjusting for Automation

A closer look at how automation impacts your workforce and their skill sets

When component manufacturing operations decide to increase the level of automation in their facility, they expect it to have a significant impact on productivity. What they may not fully consider is the extent to which it will impact the attitude and effectiveness of their current employee base. The success of their employees in a more automated environment depends heavily on what the employer does to communicate and train in preparation for the transition.

When component manufacturing operations decide to increase the level of automation in their facility, they expect it to have a significant impact on productivity. What they may not fully consider is the extent to which it will impact the attitude and effectiveness of their current employee base. The success of their employees in a more automated environment depends heavily on what the employer does to communicate and train in preparation for the transition.

Confront the Fear Factor

“One of the fears that most line workers have is, ‘You are replacing my job,’” says Jason Blenker, president and CEO at Aedifix Builds, who consults with companies in the industry, capitalizing on his experience implementing advanced automation. “The truth is, I’m not replacing their job. I’m filling one or more jobs that I can’t fill otherwise. It’s the next person that we can’t find. My job as an employer is to make sure I tell them we’re giving them a new set of skills, so that they are even more valuable to us. I’m investing in them for future skills, not for work that they no longer have to do. The problem is we’re still swinging hammers, the oldest tool that man invented. There is a place and a time for craftsmanship, but when dealing with many of our industry’s products, there’s a better way.”

The point is that when workers hear “automation,” they worry their jobs will go away. Some even catastrophize. Think of the Luddites or poor John Henry who died after “beating the machine.”

“Pablo, one of our best sawyers under the traditional build process, was begging us to not automate,” says Steve Broadbent, VP of Specialty Products at Sunpro. “He wanted no part of it.” Broadbent attributes part of their organization’s success transitioning to an automated system to the fact that leadership regularly monitors productivity as well as the employees’ success within the automated system. Most importantly, they listen to feedback from employees and adjust when necessary.

“Pablo, one of our best sawyers under the traditional build process, was begging us to not automate,” says Steve Broadbent, VP of Specialty Products at Sunpro. “He wanted no part of it.” Broadbent attributes part of their organization’s success transitioning to an automated system to the fact that leadership regularly monitors productivity as well as the employees’ success within the automated system. Most importantly, they listen to feedback from employees and adjust when necessary.

“As with anything new, you are going to run into unexpected issues and you will be forced to rethink how to do things,” Broadbent continues. “In our case, we were constantly on the phone with our supplier’s engineers in Germany and working through things. It was a process to work through each issue, but good communication with our employees who are living and doing it every hour made a big difference. Pablo has become a champion of troubleshooting or understanding why something is going wrong.”

Emphasize the Benefit to the Worker

When implementing an automated process, it can also be effective to build employee buy-in by pointing out the ways the new system will take the burden off them from doing repetitive, dangerous, or otherwise physically demanding tasks.

“A lot of that work can involve repetitive movements. The twisting, turning, lifting,” says Blenker. “Fortunately, we’ve never had a major accident. Just minor cuts and sprains. But even with those, if we can eliminate minor injuries, why wouldn’t we?”

As work becomes automated, employers can have greater success if they proactively work to train those same workers to use their new tools to improve productivity. To that end, it’s important to clearly communicate the reasons the company is adding automation, emphasizing the benefits it brings to both the organization and the employees. Be clear in all communications that the improved efficiency does not directly translate into the loss of existing jobs; it changes the nature of the jobs.

As work becomes automated, employers can have greater success if they proactively work to train those same workers to use their new tools to improve productivity. To that end, it’s important to clearly communicate the reasons the company is adding automation, emphasizing the benefits it brings to both the organization and the employees. Be clear in all communications that the improved efficiency does not directly translate into the loss of existing jobs; it changes the nature of the jobs.

“Our goal was really to speed up the slowest part of the build process, which is the table for us, and deliver in a way that optimized the build process. Ultimately, it was about reducing the number of people we need to get the same or greater output,” says Broadbent. “We just can’t get enough people to continue building in the traditional manner and get to where we want to be as a company. We have no plans to reduce the workforce as part of adding automation to the work line. We want to be more productive.”

Communicate and Train Proactively

Organizations can help ensure a smoother transition to automation while maintaining a positive work environment and supporting the growth and development of their current employees. One way is to regularly update your team on the progress of automation initiatives and how they align with the overall company goals. You may need to redesign job roles to capitalize on the strengths of both humans and automation.

“We needed a way to better harness the capabilities of our existing workforce, recognizing we are having a smaller and smaller candidate pool applying for today’s jobs,” Broadbent goes on to say. “We started with a baby step. Automation is a long process that has a long learning curve. As we automate the entire process, there are things to learn before we get there. We have already learned valuable lessons just automating this part of the process. We have encountered an issue at every step, and one by one identified special skills that we will need to develop.”

“We needed a way to better harness the capabilities of our existing workforce, recognizing we are having a smaller and smaller candidate pool applying for today’s jobs,” Broadbent goes on to say. “We started with a baby step. Automation is a long process that has a long learning curve. As we automate the entire process, there are things to learn before we get there. We have already learned valuable lessons just automating this part of the process. We have encountered an issue at every step, and one by one identified special skills that we will need to develop.”

To use the capabilities of all workers as they transition over time, most operations will need to have a mix of employees who are cross-trained in both the traditional production methods as well as those engaged with automation. Success comes from proactively offering training programs to help employees acquire the necessary skills to work within new automated systems.

“Moving from a more manual to more automated system is a big change, particularly in how we train our people and manage the workflow,” says Chris Ortiz, maintenance engineering manager, of Louws Truss Inc. “We have cross-trained three or four people to adapt to the new process, and it’s worked out well. In addition, when hiring, we look for people who have more of a proactive problem-solving mentality. Everyone we have is capable of doing the work, but we now try to identify more technically-minded individuals to work with the automated machines.”

Adapt Expectations and Encourage Learning

One thing leadership teams can do is encourage continuous learning and development to ensure employees remain valuable contributors to the organization. The changing roles and responsibilities of production workers in a transition to greater automation require a new look at the behavioral attributes, cognitive abilities, and competencies required for success in new production roles. In the past, a natural focus on adherence to rules and a longer ramp-up in learning were suitable for most jobs, and compliance was required.

“It does take a higher level of attention to detail and that’s one thing we look at - there’s skill in making trusses and different skills in running these systems,” said BJ Louws, president of Louws Truss. “When there’s an error code, you have to have the knowledge to know where the error is coming from, whether to clear it or not. There are visual checks, and you have to do them quickly and efficiently. It can be costly when you’re down. They need proficient decision-making skills to maintain a high level of up time.”

Employers still need that task-focused individual who is helpful and adherent to rules, but with a willingness to learn and with more proactive problem-solving skills. “As employers, we need to make sure they understand what their new role is in the system,” Blenker adds. “When we did the cost benefit to get it up and running, it took a lot of training with the new technology and understanding different problems than they had in the past.”

Bottom Line

One key element of a successful transition to a more automated production system is ensuring that existing employers fully understand why the company is implementing the change and assure employees they aren’t being replaced with a machine. It’s also important that employees are well aware of the benefits they will realize through the new system with regard to health and safety. During the implementation period, communication and proactive training are essential, as well as fostering a work environment that encourages workers to continually learn about the full capabilities of the new system.

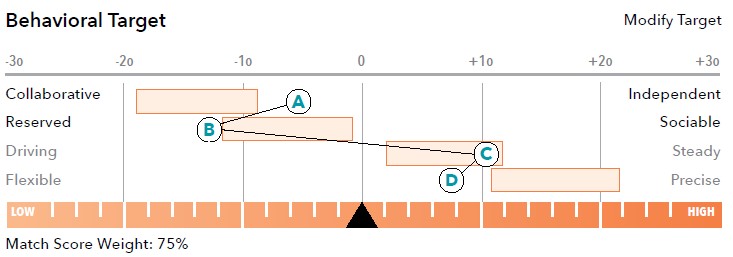

Business Results works with clients in the component manufacturing industry and provided the above Predictive Index (PI) profile for a production line worker. The ideal candidate is attentive to details and will follow rules and established procedures. The individual appreciates clear instructions and learns at a normal pace. He or she should be able to analyze problems effectively and solve complex issues as they arise, and work well under a formal framework with precise rules. This person strives to do quality work.

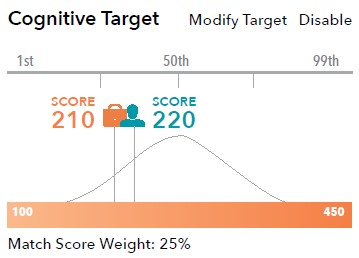

Trained properly, this individual would thrive, whether the production process is traditionally manual or more fully automated. What changes from a new hire perspective is that a company would likely want to focus more on a person’s cognitive target (at right) and their capacity for analytical thinking. This is a particularly important skill when it comes to troubleshooting complex automated machinery.

About the Author: Dolly Penland, President & CEO of Business Results, a PI® and CATIL Certified Partner and Talent Optimization consultancy, works with organizations to help them hire and manage their talent to their highest potential. She specializes in multiple areas including business sales growth, turnover reduction, and leadership development.