Hem Fir (N) Design Value Reductions Approved by ALSC Board of Review

Originally Published by: SBCA Magazine by SBCA Technical Director, Greg Greenlee, P.E. — November 5, 2024

SBCA appreciates your input; please email us if you have any comments or corrections to this article.

Understanding the Grading Agencies Roll

Softwood lumber species groups are regularly subjected to established testing protocols to ensure they retain their published design values over time. In North America, there are six grading agencies that have jurisdiction over establishing softwood lumber design values and are responsible for conducting ongoing testing to verify them. Those grading agencies are:

- National Lumber Grades Authority (NLGA)

- Northeastern Lumber Manufacturers Association (NELMA)

- Redwood Inspection Services (RIS)

- Southern Pine Inspection Bureau (SPIB)

- Pacific Lumber Inspection Bureau (PLIB/WCLIB)

- Western Wood Products Association (WWPA)

Each of these grading agencies follow grading rules approved by the American Lumber Standard Committee’s (ALSC) Board of Review (BOR) and are certified for conformance with the U.S. Department of Commerce Voluntary Product Standard (VPS) process. For softwood lumber used in the U.S., the VPS is maintained by the ALSC and is referred to as American Softwood Lumber Standard PS 20 (PS 20). The current edition is PS 20-20.

Once each grading agency completes its regular testing protocols, it is required to report the resulting data to the ALSC BOR, along with any recommendations it has regarding changes to current published design values. Fortunately, changes are rare, but occasionally they happen.

What is Changing?

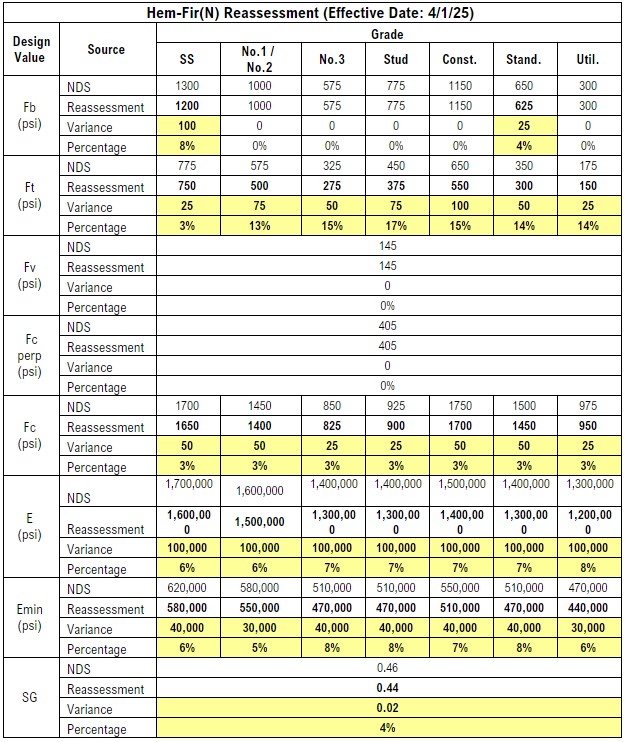

Earlier this month at the ALSC Board of Review meeting, the Board reviewed and approved the National Lumber Grades Authority’s (NLGA) reassessment study report for Hem Fir (N). The results of this study recommended reducing some design values for Hem Fir (N). Where reduced, the magnitude of reduction was roughly between 5 and 15 percent.

Hem Fir (N) is a Canadian lumber species group consisting of Western hemlock and Amabilis fir typically harvested in British Columbia. The grade stamp identification is “Hem-Fir (N)”. It is different than Hem Fir, which is part of the WWPA and PLIB/WCLIB grading system, and is a species group consisting of Western hemlock and five of the true firs: California Red fir, Grand fir, Noble fir, Pacific Silver fir, and White fir. The largest strands of Hem Fir are found on the western slopes of the Cascade Range in Oregon, Washington, British Columbia, and Alaska. The grade stamp identification for Hem Fir is “Hem Fir”, without the “N”.

A table comparing the current design values with the new design values is shown below. Reassessed values that are less than the current NDS values are shown in bold and highlighted, with the magnitude and percentage of reduction included.

The implementation date for this revision is April 1, 2025. The American Wood Council (AWC) is planning to issue an Addendum to the 2024 NDS Supplement when the new design values become official.

The implementation date for this revision is April 1, 2025. The American Wood Council (AWC) is planning to issue an Addendum to the 2024 NDS Supplement when the new design values become official.

What Do These Values Mean?

The design values provided by grading agencies are used in the design of wood members and connections. For metal plate connected wood trusses, these values are used with the design provisions provided in ANSI/TPI 1. The following is a brief description of each of these design values and how they are used:

Fb – Fiber stress in bending. This is used for flexural design calculations such as a beam or chord of a truss subject to bending forces.

Ft - Tension stress parallel-to-grain of lumber. Determines how lumber will react to axial tension loads applied across its whole cross section. This is pertinent for truss web and chord members.

Fv - Horizontal shear stress. It is the force required for the layers within a piece of lumber to slide past each other. It is used in beam design and typically more critical in short heavily loaded beam and is a design check at the bearing end of trusses.

Fc - Compression parallel-to-grain. Determines the strength of a piece of lumber across the whole cross section then loaded axially in compression.

Fc perp - Compression perpendicular-to-grain. Determines the bearing capacity of a piece of lumber loaded on its side, such as the end of a truss.

E - Modulus of elasticity. Measures the amount a piece of lumber will deform in proportion to an applied load. It is a measure of stiffness and not a strength property. This is used for deflection calculations.

Emin – Minimum modulus of elasticity. This is the minimum value for the modulus of elasticity that may be assumed for a specific species and grade. This is used for stability and buckling calculations.

SG – Specific gravity. A ratio representing the density of water to the density of wood. It is used to develop tooth holding capacities from test results.

How Does This Impact Us?

Component manufacturers that use Hem Fir (N) need to be aware of these changes and be prepared for the April 1, 2025, implementation date. Impacts on component designs should be understood so that material ordering and inventory levels can be managed appropriately. It is important to note that Hem Fir (N) is a different species and is regulated by a different grading agency than Hem Fir. The changes to the Hem Fir (N) values do not impact the published values for Hem Fir. Refer to the article, Seeing the Lumber Amongst the Trees in the May/June 2024 issue of the SBCA Magazine for an understanding of the lumber grading process, grading agencies, lumber species, and lumber grades used in the industry.