Simple and Elegant

Truss headers can really shine in challenging design situations

Building designers love simple solutions. One such solution is a trussed rough opening (TRO) or trussed header. For many wall rough openings, a simple 2x_ header is sufficient. Rough openings for large windows or multiple window sets typically need headers framed using LVL or a similar engineered wood product (EWP) to provide sufficient load resistance. These solutions work fine for most applications, but in Type III-A buildings, for example, when the exterior walls need to have a two-hour fire rating, using LVL or other EWP can present a challenge to building designers. Enter the TRO.

TRO Origins and Promotion

“Building designers in our market were looking for a better solution to large opening headers,” says Tony Acampa of Shelter Systems Limited. “It started with the Type III-A buildings because the two-hour fire rated assembly for the exterior walls is difficult to achieve with normal wood products. When we looked at the problem, a parallel chord truss made of fire treated wood (FTW) seemed to be a simple alternative.”

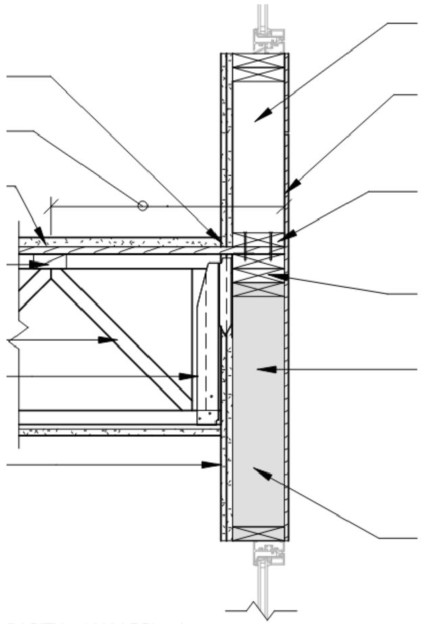

Illustration 1: Example detail of a TRO that can be built from fire-retardant-treated (FRT) wood and integrated (highlighted in grey) into a two-hour rated fire assembly.

Illustration 1: Example detail of a TRO that can be built from fire-retardant-treated (FRT) wood and integrated (highlighted in grey) into a two-hour rated fire assembly.

The idea behind the TRO is to harness the strength and efficiency of the load triangulation within the metal-plate connected wood truss and, similar to its application in floor systems, use it to span the areas above large rough openings.

It should be noted that while 4x2 trusses can excel in this application, Shelter Systems also produces 6x2 trusses to match the depth of the exterior walls in their market. “Either dimension will work, you just need to pad the header area when you use a 4x2 truss on a 6-inch-deep wall,” says Tony.

Just like any truss designed to carry loads between two or more bearing locations, the truss header’s design will need to be reviewed and approved by either the building’s engineer of record, the building designer, or an independent professional engineer (as required by the applicable building code). Once Shelter Systems had success with TROs on a few Type III-A projects (e.g. wood construction over four stories), they started promoting this framing approach to the architects and engineers in their market. “We took every opportunity to talk about this solution with building designers as we evaluated plans,” says Tony. “Its simplicity was what really resonated with them, and soon we started seeing it specified on more and more plans.”

As a pleasant surprise, building designers didn’t limit the TRO specification to only Type III-A buildings, but expanded their use to Type V-A (e.g. wood construction four stories or less). “With the lesser one-hour fire rating needed for exterior walls, there are more solutions available to the building designer and yet we see them continuing to specify the TROs,” Tony explains. “That likely has to do with all the additional benefits this approach opens up.”

Design Benefits of TROs

Beyond the initial fire-rated assembly solution, TROs also give building designers two additional advantages. The first is a structural solution that provides a popular aesthetic. TROs can be designed to almost any depth and are limited only by the capabilities of a company’s production equipment. One consequence of this is that the header truss can be designed exactly three inches less than the depth of the building’s floor trusses to fit in-between floors and allow for a double top plate. “Placing the header in the floor truss system allows building designers to accommodate windows that run all the way from floor to ceiling in these balloon-framed walls,” says Tony (see Illustration 2). “The key is the ability to size the truss header to any depth you need.”

Illustration 2: Example detail of a TRO that is designed to match the depth of the floor truss and enable building designers to extend the rough opening from the floor to the ceiling.

Illustration 2: Example detail of a TRO that is designed to match the depth of the floor truss and enable building designers to extend the rough opening from the floor to the ceiling.

Tony goes on to say, “TROs also allow building designers to create a cleaner exterior look more easily using any external exhausts or pipes. “The truss header gives the architect the ability to have an exact placement for things like dryer vents or pipes to create an exterior symmetry that’s hard to accomplish when the trades have to drill holes through LVL or other materials.”

Finally, the open web design of the headers can also improve the energy performance of the building by allowing for the application of insulation within the header. This can drastically reduce the typical thermal bridging that occurs in solid wood or EWP headers and allows the building designer more options when it comes to exterior wall insulation.

Labor Benefits of TROs

Building designers aren’t the only stakeholders that benefit from the use of TROs. Framers realize significant time savings and a reduction in the skill level required, because it is considerably easier to install truss headers than measure, cut, and build truss headers made of 2x_ material, LVL, or other EWP. “Because the truss header depth can be adjusted by the designer for different rough openings, you can just install them versus having to add additional framing material like cripples to make it fit,” Tony goes on to say. “It really simplifies the process for the field labor so they can focus their attention on other complicated aspects of the project.”

Again, the other trades also potentially benefit from the use of TROs if they have to install plumbing, duct work, or electrical to the exterior of the building, because the trusses can be designed to provide consistently spaced and appropriately sized openings for any infrastructure. “It cuts down on mechanical installation time and potential errors or situations in which the framing might get compromised,” Tony continues. “We regularly hear back that the truss header makes everyone’s lives easier on the jobsite.”

TROs can be used in a variety of projects from Type III-A to Type V-A, and for both exterior and interior applications.

Tony admits the truss header is usually not the least expensive framing option, but given all that it can accomplish, from design flexibility to labor time and error reductions, it is likely a more cost-effective solution from the perspective of a project’s bottom line. In some cases, the truss header may be integrated into a fully-framed rough opening at the manufacturing facility and shipped to the jobsite, but most of the time Shelter Systems manufactures only the truss header, and it’s the framers in the field who install them into walls framed onsite. “It’s really up to the preference of the framer or customer,” says Tony. “We’ve done it both ways, but in the current market most customers want just the truss header.”

Wider Applicability?

Shelter Systems does not claim to have invented the truss header concept, but they have had great success promoting it to the building designers in their market to the point where it is now specified on most of the plans they receive.

Other truss manufacturers have offered TROs for years, and several more joined the movement when LVL and other EWP products became hard to source due to the COVID pandemic. “Having the ability to supply a header at any depth, made from a relatively easy material to source, makes truss headers a pretty elegant solution,” Tony concludes.

That flexibility is what has expanded the use of TROs from Type III-A to Type V-A. It likely will open up further opportunities for TROs in other construction types like commercial and even single-family residential. If you’re already offering floor trusses to your customers today, consider how you might be able to incorporate this beneficial structural framing solution into their next project.