The Standard Approach

ANSI/TPI 1-2022 will benefit component manufacturers in the long term

The component manufacturing industry benefits in several ways from the existence of a nationally recognized industry standard. TPI 1, the National Design Standard for Metal Plate Connected Wood Truss Construction, was originally published in 1960 and establishes minimum requirements for the design and construction of metal plate-connected wood trusses.

Because the standard lays out criteria for the materials, design procedures, and manufacturing quality assurance of trusses, every component manufacturer (CM) in the industry operates from the same foundational playbook. Further, because the standard is referenced in the building code, it helps establish a clear scope of work for CMs for the rest of the construction supply chain to reference and understand. This dramatically streamlines the design and approval process for every truss and establishes public trust in the performance of our industry’s products, as well as in the safety of the structures they are installed in. Finally, it should be noted the TPI 1 standard has been instrumental in promoting the broad acceptance of metal plate-connected wood trusses (MPCWT) over time.

After nine updates, TPI 1 was first published as an American National Standards Institute (ANSI) standard in 1995, which means it needs to be developed through what is called a consensus-based approach. ANSI is an organization that develops and enforces policies and procedures to ensure that a proposed standard incorporates the feedback of a wide range of stakeholders impacted by that standard. In the case of TPI 1, the ANSI process requires plate manufacturers, CMs, construction industry engineers, and others to periodically review and comment on the effectiveness of the standard and to propose changes to improve it as necessary.

Since 1995, the TPI 1 standard has been updated five times, the most recent being ANSI/TPI 1-2014. Starting in 2019, a project committee was formed consisting of 32 volunteer members (see sidebar) representing all the major stakeholder groups. Over the course of the next three years, committee members donated hundreds of hours developing, discussing, and contemplating the implications of numerous changes to the standard.

The committee work to update the ANSI/TPI 1-2022 standard is now complete. TPI has submitted the final paperwork to ANSI for approval as an American National Standard. TPI and its technical committees strive to ensure that the truss industry remains on a sound engineering basis and that the latest science and technology have been incorporated into the TPI 1 standard to make MPCWT the most reliable, economical, and universal solution for structural framing.

ANSI/TPI-2022 Updates

Some significant changes were made to the standard in the 2022 version. TPI’s Technical Advisory Committee (TAC) devoted numerous hours developing several technical updates that will benefit the industry and standardize certain methods that have historically been left up to individual engineers. In total, there were fifty updates approved through the consensus process in this cycle. Several were simple clarifications of terminology, but some will likely have an impact on future truss designs.

TPI 1-2022 will contain provisions that will benefit top chord bearing truss design.

It should be noted that while ANSI/TPI 1-2022 will be approved shortly by ANSI, from a practical standpoint it will not go into effect until it is incorporated into the model building code and/or adopted by local code jurisdictions. The next building code cycle will be for the 2024 IBC/IRC, which is typically not adopted for a few years afterwards. However, it’s still important to understand the changes that will eventually occur. The significant updates to the standard that CMs should be aware of address top chord bearing analysis, web reinforcement analysis, and load and load distribution requirements.

Top Chord Bearing Analysis

In past editions of the TPI 1 standard, reaction limits for a top chord bearing truss were limited to tabulated values regardless of lumber grade and connector plate size. In this update, provisions are included to analyze various conditions and include benefits of plate positioning and size, as well as lumber species and grade. A future article will explore the implications of this change and the potential benefits CMs can realize through this update.

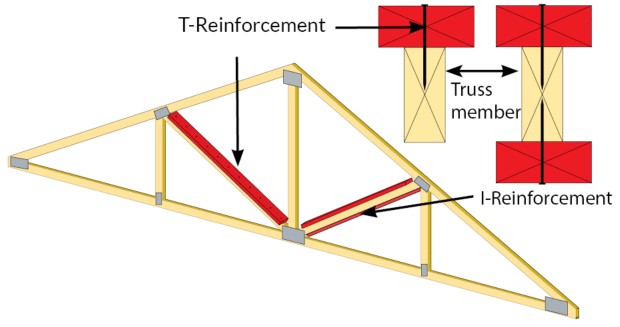

Web Reinforcement Analysis

There are prescriptive methods to reinforce webs such as T- and L-bracing when used in lieu of continuous lateral restraints. These prescriptive methods are very handy for quickly determining web reinforcement when CLRs will not work. However, in certain conditions these methods might not be economical if web reinforcement is to be used on an entire structure. The updated standard now has methods to analyze any reinforcement size or grade so the most economical solution can be determined.

TPI 1-2022 will make certain kinds of web reinforcement easier and more economical.

Load and Load Distribution Requirements

TPI 1-2022 will provide a new method for determining load distribution in individual plies of a multi-ply girder.

There are a few changes to TPI 1 that deal with truss loading, including:

a. Person Loads – A new load check was added to the standard to prevent overloading bottom chords, especially during construction and maintenance.

b. Dead loads for uplift calculations – A provision was taken out of the standard to prevent confusion about the appropriate dead load to use when checking wind uplift. This is now left to the building designer.

c. Multi-ply girder analysis – In past versions of TPI 1, there was no guidance on how load is distributed to each ply of a multi-ply girder. This was left up to the designer, and typically it was assumed that each ply carried an equal load. Research and testing have shown that this is not the case, so the standard now contains a load distribution table for each ply of a multi-ply girder loaded from one face.

Bottom Line

TPI and SBCA worked very closely together on the updates to ANSI/TPI 1-2022 to ensure that the structural building components industry’s best interests are preserved in the standard. Both organizations would like to offer up a heartfelt thank you to the members of the Project Committee for their selfless dedication to the betterment of our industry.

This article is the result of a collaboration between the members of the Truss Plate Institute’s Technical Advisory Committee (TPITAC) and SBCA. It is part of a technical article series driven by TPITAC members that seeks to address pertinent engineering topics and provide design best practices.

TPI 1-2022 Project Committee Members

Frank Woeste PhD, PE, Virginia Tech

Scott Coffman PE, SECB, Construction Science and Engineering, Inc.

Brad Cross PhD,PE,SE, Southern Illinos Universit-Edwardsville

Ahmadi Mohammad, PE

Gary Ehrlich, PE, National Association of Home Builders

David Brakeman PE, SE

Howard Gauger, R&D Thiel/CCA

David Wert, PE, MiTek USA, Inc.

Art Hernandez, PE, Eagle Metal Products

Bob Dayhoff, Shelter Systems Limited

Stuart Lewis, PE, Alpine, an ITW Company

Tim Riegel, PE, Rigidply Rafter, Inc.

Matt Vinson, PE, Eagle Metal Products

Jess Lohse, SBCA

Darren Conrad, PE, Simpson Strong-Tie

Ted Kolanko, PE, Cherokee Metal Products

Kevin Kraft, Alpine, an ITW Company

Michael Schwitter, Alpine, an ITW Company

David Conner, Timber Products Inspection, Inc.

John Gruber PhD, PE, SE,

Sheppard Engineering

Gary Obudzinski, PE, Alpine, an ITW Company

Junaidie Budiman, PE, Trussway, a Division of Builders FirstSource

Samuel Greenberg, PE, DANSCO Engineering

David Baxter PE, SE, MiTek USA, Inc.

Jason Fetterley, PE, Nederveld, Inc.

Glenn Traylor, Timber Products Inspection, Inc.

John Arne, SBCA

Abby Davidson, EIT, PFS TECO

Bill Bolduc, PE, SE, Xpert Structural Engineering

Daniel Rybicki, MiTek USA, Inc.

John Galinski, PE, MiTek USA, Inc.