Trusses are a Lock

Cussewago Truss delivers another win in the world of concrete

This is a story about commerce that is as old as our nation. It’s a story about engineering ingenuity from a century ago. It’s a story about the lingering impact of 2012’s Superstorm Sandy, one of the costliest natural disasters in U.S. history. It’s also a story about the incredible efficiency of metal plate connected wood trusses and the adaptability of today’s component manufacturer (CM).

The concrete formwork Cussewago Truss designed in 2013 that paved the way for the Charleroi Locks & Dam project.

The concrete formwork Cussewago Truss designed in 2013 that paved the way for the Charleroi Locks & Dam project.

Sandy’s Lasting Impact

Superstorm Sandy remains the largest hurricane in history, with tropical-storm-force winds spanning a diameter of 1,150 miles. It caused nearly $70 billion (in 2012 dollars) in damage, including washing out a 17,000-pound heavy-gauge steel lattice formwork installed to pour a new bridge over Walnut Creek. Located just a mile from the shores of Lake Erie, on Route 5 between Erie and Fairview, Pennsylvania, the damage threatened to set the project back by several months.

Enter Cussewago Truss, located in nearby Cambridge Springs, Pennsylvania. The contractor for the bridge project reached out to them to see if it would be possible to erect a new concrete formwork out of wood. When they discovered that it was not only possible, but that it could be done at a fraction of the expected cost, they quickly contracted Cussewago Truss for the job. The rest of that story was told in the cover feature of the March 2014 issue of SBCA Magazine, and the success of that project led to similar formwork jobs.

“Another concrete contractor heard of the work we had done on that bridge project and brought us in to do similar formwork for them over the years,” says Larry Otto, general manager of Cussewago Truss. “I think the last job we did was in 2018, so it had been a little while since we had heard from them…Then, in July 2022, they reached out and said they needed product by late August for a river lock reconstruction project. Obviously, we wanted to participate.”

“Another concrete contractor heard of the work we had done on that bridge project and brought us in to do similar formwork for them over the years,” says Larry Otto, general manager of Cussewago Truss. “I think the last job we did was in 2018, so it had been a little while since we had heard from them…Then, in July 2022, they reached out and said they needed product by late August for a river lock reconstruction project. Obviously, we wanted to participate.”

Charleroi Locks & Dam

In the 1920s and 1930s, the U.S. Army Corps of Engineers (USACE) was busy designing and constructing flood controls, including locks, dams, and levees, on navigable waters throughout the U.S. This was partially due to a push to harness hydroelectric power, but mostly to utilize major rivers to efficiently move bulk commodities such as coal, lumber, and grain over long distances.

The Charleroi Locks & Dam was originally built by the U.S. Army Corps of Engineers in 1932.

The Charleroi Locks & Dam was originally built by the U.S. Army Corps of Engineers in 1932.

In 1932, the USACE finished construction of the Charleroi Locks & Dam, one of nine navigational structures on the lower Monongahela River that runs between Pittsburgh, Pennsylvania, and Fairmont, West Virginia. The Charleroi Locks are unique in that they have two working locks - the second was added in 1967 - and the gated dam controls water levels for the 19.7 miles between it and the next dam upriver.

“The dams are essential to river commerce,” says Stephen Dine with USACE. “The barges require a nine-foot-deep pool and without the dams you could walk through some sections of the river.” The barges are cost-efficient because they require less energy and people to transport over similar distances, but they are also more environmentally friendly. These benefits are obvious to the mines, quarries, and agricultural entities that rely heavily on this water navigation.

Illustration 1

Illustration 1

“The barges have gotten a lot bigger over the last 100 years since the structure was built,” says Stephen. “Today, they push double rows of jumbo barges down the river and to get through the locks they have to break them up, take half through and secure them, navigate the other half through the locks, and then join them all back up.” Stephen estimates that the process can take as long as two hours to complete, but after the new locks are completed, it will take less than 30 minutes for the barges to get through.

“When you consider that each barge today can carry the equivalent of 150 rail cars, the lock expansion project will be very beneficial to commerce, since it can move a lot more tonnage through the river system much more quickly,” says Stephen. To that end, USACE has budgeted nearly $1 billion to improve navigation on the Monongahela River, and the Charleroi Locks & Dam is the last major project in that effort.

Time- and Cost-Efficient Formwork

The Charleroi Locks & Dam project required a lot of concrete construction. In addition to the construction of two new 84-feet wide lock chambers (the previous locks were 56-feet wide), a new 884-foot river wall is being built to improve navigation. As part of the new lock chambers, contractors had to fabricate and install custom large fill/emptying valves with mechanical embeds.

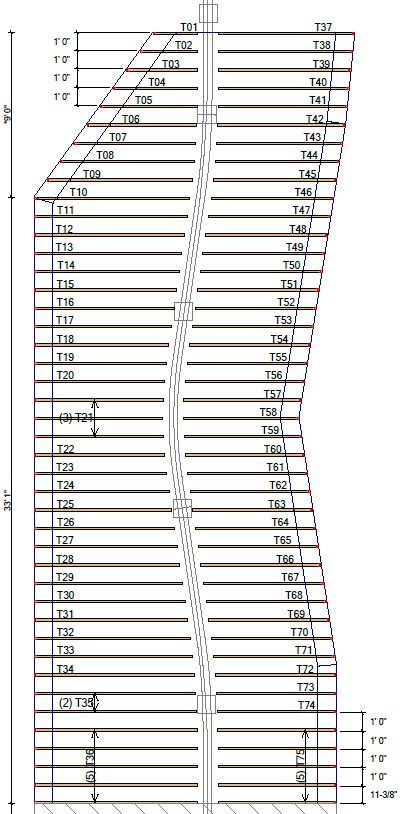

Those valves and mechanicals were housed in concrete structures built 20 feet under water. The floor and sides of each 84-foot-long structure spanning the lock were constructed with concrete in the riverbed, and a steel hoist beam was installed, running roughly down the middle of it (see Illustration 1). “The structure has a maximum span of 17 and a half feet, and there was a steel hoist I-beam that curved all the way down the length of the housing,” explains Brian Otto, senior designer for Cussewago Truss. “To accommodate the hoist beam, I had to split each span between two trusses, with the longest span ending up being around nine feet long.” The truss formwork would be supported by temporary shoring and decking installed beneath (see Illustration 2).

Illustration 2

Illustration 2

The real challenge was that, instead of roof trusses designed to accommodate typical deadloads found in light-weight construction, this roof had to resist a 465-pound deadload on the top chords. “The trusses had to resist a three-foot thick, poured-concrete roof,” says Brian. “It was different from the normal problem-solving encountered in truss design, but fortunately we also had the help of the engineers at Eagle Metal Products.”

To add to the cost-efficiency of the metal-plate-connected wood truss concrete formwork, Brian designed trusses that run 42 feet, or half the length of the embedded structure (see cover). “They set up the trusses and poured the roof for half the structure,” he explains. “Once the concrete cured, they went in and removed the trusses and temporary shoring and decking, and set them back up for the other half of the roof.”

The wood trusses were installed to create the formwork for half the length of the structure. Once the concrete was poured and set, the trusses were moved to create the formwork for the second half of the structure. This approach provided a quick and incredibly cost-efficient solution.

The wood trusses were installed to create the formwork for half the length of the structure. Once the concrete was poured and set, the trusses were moved to create the formwork for the second half of the structure. This approach provided a quick and incredibly cost-efficient solution.

In addition to being much less costly than steel formwork, they were time-efficient. From the moment Cussewago Truss was contacted by the contractor, the wood trusses were designed, manufactured, delivered, and installed within a two-month window! Installation took less onsite labor and equipment because of the relatively light weight of the individual wood truss elements as compared to steel.

The Bottom Line

The Bottom Line

The Charleroi Locks & Dam have played a vital role in commerce and the local economy for almost a century. To reflect the growing dependence on the navigable waters of the lower Monongahela River between Pittsburg, Pennsylvania, and Fairmont, West Virginia, the USACE has budgeted nearly $1 billion to improve the infrastructure along the river.

While just one part of this immense project, the metal-plate-connected wood trusses designed and manufactured by Cussewago Truss proved to be an incredibly cost- and time-efficient formwork solution to pouring the three-foot-thick concrete roof on the lock’s value and mechanical housing embedded 20 feet under water. This project proved once again that wood trusses can be a valuable framing

solution beyond their typical use in light-framed buildings.