SBCA Holds First Regional Quality Bootcamp

Originally Published by: SBCA Magazine — February 25, 2025

SBCA appreciates your input; please email us if you have any comments or corrections to this article.

SBCA hosted its first Quality Bootcamp on February 11-12 in Phoenix, AZ. Thirty component manufacturers, associates, and staff attended the Southwest Bootcamp and, over the course of two days, took a deep dive into what it really means to have a thorough Quality Program at a component manufacturing plant.

From classroom-style training to hands-on workshops throughout the event, the attendees went back to the basics by learning how to create and maintain a consistent, thorough Quality Program and ended the second day with applied training using both paper/vellum inspection, SBCA’s Digital QC app, and the Digital QC server reports.

One of the first and most important aspects of a Quality Program is understanding the difference between quality control (QC) and quality assurance (QA), and the important roll each play. SBCA’s Technical Director, Greg Greenlee, P.E., and SBCA’s Managing Director, Molly Butz, kicked off the 2-day event with an in-depth review of management responsibilities, ANSI/TPI 1 requirements, building code requirements, and third-party QA audits.

Attendees were pleased with all of the detailed information during the sessions. “I think some of the most valuable information was gaining a better understanding of the expectations in the building code,” says Brian Schultz, Plant Manager at Timberline Truss. “Some of it is clear and some is a little grey, but Greg explained it well.”

The hands-on workshops throughout the bootcamp allowed attendees to roll their sleeves up and get close and personal with the QC process. The inspection procedure is very detailed, and working through the paper inspection form was eye-opening for many people, particularly those that have only used Digital QC. It was clear to attendees how much easier and faster it is to do inspections using the Digital QC app, which drove home the importance of quickly and properly collecting the data they need to fuel their in-plant quality programs.

Heather Jantzen, with Copperstate Truss's Operations and Sales team, liked learning how she can really dial in her company’s in-plant quality program. “Seeing the software’s capabilities for analyzing data was incredibly valuable. We’ve already implemented changes in our digital QC process to improve data collection, which will help us steer future improvements in plant quality and efficiency.”

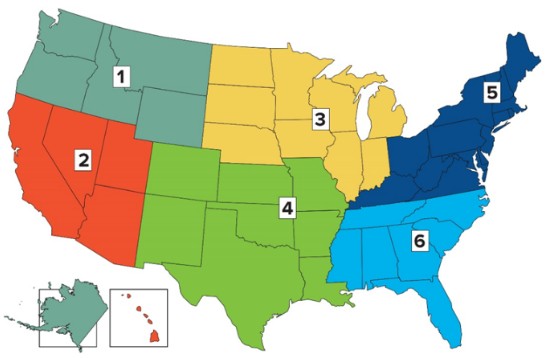

SBCA’s Bootcamps are planned throughout the country intending to hit each region at least once in 2025. The current schedule is as follows (but is subject to change):

- Region 2: Phoenix, AZ – February 11-12, 2025

- Region 6: Mt. Pleasant, SC – March 10-11, 2025

- Region 3: Minneapolis - April

- Region 5: Washington D.C. - June

- Region 1: Spokane - July

- Region 4: Dallas/Fort Worth/Oklahoma City - November

- Region 2: Sacramento, CA - December

Learn more about the Quality Bootcamps at https://www.sbcacomponents.com/quality-bootcamps or register to attend the next Bootcamp in Mt. Pleasant, SC here: https://www.sbcacomponents.com/events/southeast-quality-bootcamp---charleston.