Guidance on Permanent Bracing for Long Span Trusses

Originally Published by: Frame Building News — March 28, 2022

SBCA appreciates your input; please email us if you have any comments or corrections to this article.

Bellbottoms. Mullets. Lime-green shag carpet. Some things are just meant to be discarded, either because they’ve served their usefulness or a better alternative has been discovered. In the case of truss bracing and lateral restraint, there is a big difference between temporary bracing, which serves a useful purpose during installation, and permanent bracing, which serves a purpose throughout the life of the building. The last article in this series looked at best practices surrounding the application and use of temporary bracing (see “Embrace Diagonal Bracing” in the January 2022 issue of Frame Building News), and this article will do the same for permanent bracing.

As has been stated several times in this series, metal plate-connected wood trusses are incredibly efficient at spanning long distances by distributing applied loads through compression and tension webs to wall bearing locations. This is why trusses are so often used in post-framed buildings to create large interior spaces. However, while trusses are very good at transferring loads within their vertical plane, trusses will tend to buckle out of plane if they do not have sufficient lateral support. The longer the truss span, the greater the tendency to buckle.

This series has focused heavily on how to prevent, or at least minimize, conditions that would cause a truss to buckle, from how they are stored and hoisted, to how they are stabilized during the construction process with temporary bracing methods. It’s critical to note the installer’s job isn’t done once the trusses are erected. In most cases, while temporary bracing is removed to affix sheathing and add other building elements, permanent bracing and lateral restraint must be installed to ensure the trusses perform as intended throughout the life of the building.

Chapter B3 of the Building Component Safety Information (BCSI-B3) includes this cautionary language in its introduction:

WARNING: Disregarding Permanent Individual Truss Member Restraint and Permanent Building Stability Bracing (PBSB) recommendations is a major cause of truss field performance problems and has been known to lead to collapsed roof and/or floor systems. Failure to install the proper restraint and bracing will greatly increase the probability of truss performance problems or an accident resulting in property damage, personal injury or death.

BCSI B-3 makes clear after this warning that not only do roof truss systems typically rely on Permanent Building Stability Bracing (PBSB) to transfer lateral loads from the truss system into the support structure (walls), but that certain trusses within the system may also require permanent lateral restraint and/or bracing to prevent buckling under assumed design loads.

Permanent bracing, like temporary bracing during the installation process, provides stability to the truss system by supporting the trusses at right angles to the plane of the trusses. Per BCSI B-3, permanent bracing performs several functions:

- Preventing out-of-plane buckling of certain truss members due to compression forced developed under the specified design load conditions.

- Maintaining the proper truss spacing.

- Resisting and transferring the lateral loads applied to the truss system (e.g., wind, seismic, snow, etc.)

Permanent Bracing for Each Truss Plane

Pay particular attention to the wood or metal purlins often used as bracing for trusses spaced greater than four feet on center (o.c.). BCSI B-3 cautions the material used for these purlins must be properly sized and fastened to the top chord of the trusses in accordance with the specifications provided in the building’s construction documents. It notes that purlins alone will not adequately brace or prevent buckling of the top chords, they must be braced diagonally with permanent members. Without this diagonal bracing, all the purlins do is ensure the top chords of the trusses will all buckle in the same direction.

Again, per B-3, the permanent diagonal bracing can be provided multiple ways, including:

• Installing diagonal bracing to the top chord plane at each end of the building at intervals along the length of the building, as specified by the building designer, to provide rigidity and to transfer the restraining forces from the purlins to a lateral force resisting system (e.g., braced wall panels, shear walls, braced frames, etc.)

• Attaching structural sheathing directly to the purlins.

The second bullet point is likely an installer’s preferred approach, but it’s critical to understand that not all sheathing products provide sufficient structural resistance. The building designer is responsible for determining if the sheathing can be used as part of the permanent bracing of the top chord plane.

Because most post-frame buildings don’t typically have gypsum panels affixed to the bottom chords, permanent lateral restraint should be affixed to the bottom chords at the spacing indicated by the building designer using appropriate stress-rated lumber.

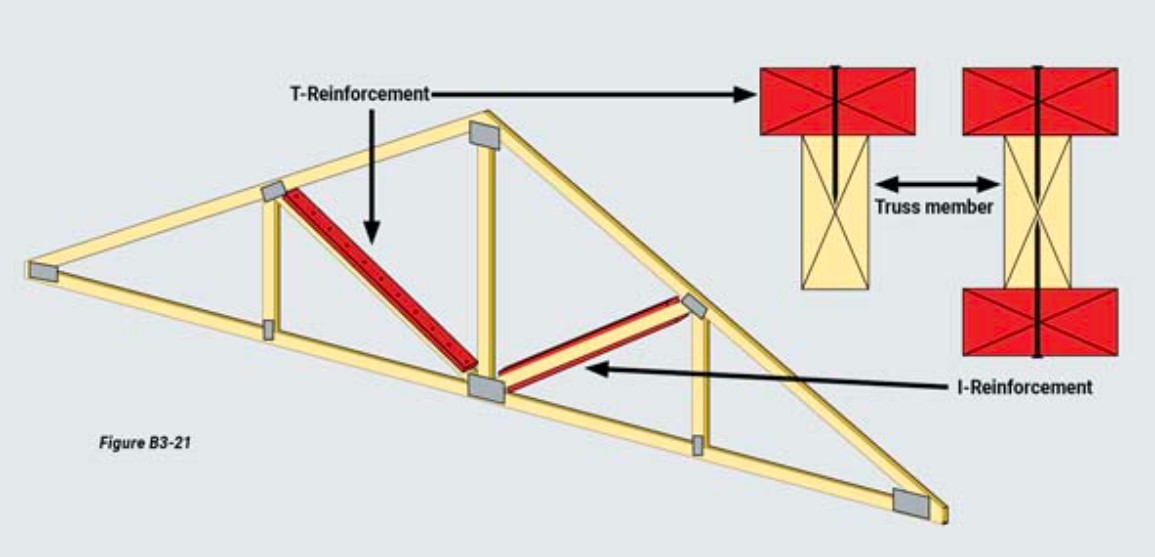

Within the web member plane, some webs require restraint and diagonal bracing to prevent out-of-plane buckling when subjected to anticipated design loads. Web member restraint is sometimes accomplished by reinforcing a member with additional material to increase its cross-section. A truss design drawing (TDD) will indicate if and where web members require this type of restraint.

T-, L-, scab, I-, or U-reinforcements are five options that involve adding lumber to increase a web’s ability to resist buckling. It is typically used as an alternative to the combination of permanent continuous lateral restraint (CLR) and diagonal bracing when they aren’t possible or desirable. The size, grade, ad species of web reinforcement materials, as well as the nailing schedule for attaching the reinforcement to the web, is typically specified in the TDD, but it can sometimes be specified separately in the construction documents.

The Bottom Line

Truss installation isn’t complete until permanent bracing is added to a truss system to ensure it performs as expected over the life of the building. BCSI B-3 provides excellent guidance on how to adhere to the Permanent Building Stability Bracing (PBSB) plant provided by the building designer. Failure to apply these important elements to the truss system may result in poor building performance and even failure of the truss system, leading to undesirable outcomes including callbacks and possible injuries or fatalities.